Introduction

In today's rapidly evolving world, metal fabrication has become a cornerstone of many industries, driving innovations that not only enhance efficiency but also pave the way for future advancements. The term metal fabrication encompasses a broad range of processes, including Mig welding, Tig welding, Arc welding, and more specialized techniques like plasma welding. These methods are crucial in creating everything from automotive components to intricate machinery used in aerospace. This article delves into the latest innovations in metal fabrication that are shaping our future, emphasizing the importance of skilled metal fabrication services and the role of safety protocols in welding.

Metal Fabrication Innovations That Are Shaping Our Future

The landscape of metal fabrication is undergoing an extraordinary transformation with the introduction of cutting-edge technologies and innovative practices. As industries strive for greater efficiency and sustainability, newer methods such as robotic welding automation, additive manufacturing (3D printing), and advanced materials are becoming increasingly prominent.

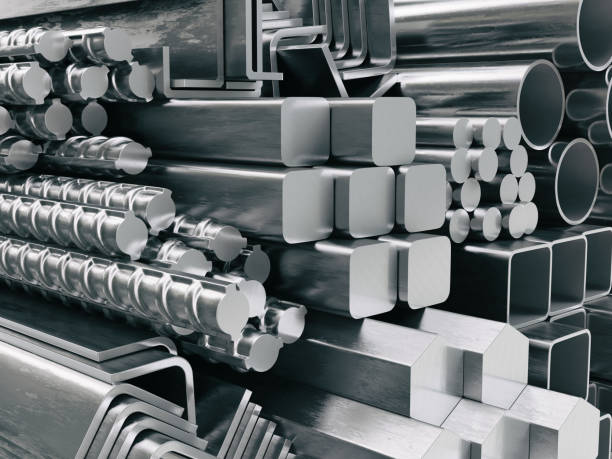

What is Metal Fabrication?

Metal fabrication refers to the process of creating metal structures and components from raw materials through various methods such as cutting, bending, machining, and assembling. The result is often a finished product that meets specific design requirements for various applications.

Key Processes in Metal Fabrication

Cutting: This involves removing material from a larger piece to achieve the desired shape or size.

Bending: This process alters the material's shape without losing its integrity.

Machining: Utilizing tools to remove materials from workpieces to achieve precise dimensions.

Welding: A vital step in metal fabrication where two or more parts are joined together using heat or pressure.

The Significance of Welding Techniques

Welding techniques play an integral role in metal fabrication. Each method has its unique advantages suited for different scenarios:

- Mig Welding: Known for its versatility and speed, Mig welding is commonly used for thin materials. Tig Welding: Offers high-quality welds with excellent precision, making it ideal for stainless steel and non-ferrous metals. Arc Welding: A traditional yet powerful technique utilizing electric arcs to melt metals. Plasma Welding: Provides high-quality welds on thin materials through a focused arc.

Understanding these processes allows manufacturers to choose the right approach for their projects.

The Rise of Robotic Automation in Metal Fabrication

One groundbreaking innovation transforming metal fabrication is robotic automation. Robots equipped with advanced sensors can perform repetitive tasks with enhanced precision and speed compared to human laborers.

Benefits of Robotic Automation

- Increased productivity due to reduced cycle times. Enhanced quality control as robots maintain consistent performance. Improved safety by taking on hazardous tasks typically performed by humans.

Additive Manufacturing: 3D Printing Metals

Additive manufacturing has emerged as a game-changer in metal fabrication. This technology allows manufacturers to create complex geometries that were previously impossible or economically unfeasible with traditional methods.

Advantages of 3D Printing Metals

Design Freedom: Designers can create intricate shapes without worrying about tooling constraints. Material Efficiency: Reduces waste by using only the necessary amount of material. Rapid Prototyping: Speeds up product development cycles significantly.Advanced Materials Revolutionizing Metal Fabrication

The introduction of advanced materials such as titanium alloys and high-strength steel has greatly enhanced metal fabrication capabilities. These materials boast superior strength-to-weight ratios, corrosion resistance, and durability.

Characteristics of Advanced Materials

- High Strength-To-Weight Ratio Resistance to Corrosion Enhanced Thermal Stability

Sustainable Practices in Metal Fabrication

As global awareness about environmental issues rises, sustainable practices within metal fabrication have gained momentum. Manufacturers are now implementing eco-friendly processes aimed at reducing waste and energy consumption.

Key Sustainable Practices Include:

Recycling scrap metal to minimize waste. Utilizing energy-efficient machines and equipment. Employing eco-friendly welding techniques that reduce harmful emissions.Mobile Welding Services in Phoenix: Meeting Local Demand

With an xpress mobile welding A1 Garage Doors Gold Coast increased demand for convenient services, mobile welding has emerged as a popular option for both residential and commercial clients in Phoenix.

Advantages of Mobile Welding Services

- Convenience: Professionals come directly to your location, saving time and effort. Flexibility: Ideal for emergency repairs or urgent projects that need immediate attention. Cost-Efficiency: Reduces transportation costs associated with moving heavy components.

The Importance of Welding Safety Standards

Safety should always be paramount when engaging in any form of welding or metal fabrication work.

Essential Welding Safety Practices Include:

Wearing appropriate Personal Protective Equipment (PPE) such as gloves, helmets, and protective clothing. Ensuring proper ventilation when working with fumes from welding processes. Conducting regular safety training sessions for employees involved in welding activities.Innovations in Welding Equipment Technology

The advancements in welding equipment have made it easier than ever to achieve flawless results while ensuring worker safety during operations.

Latest Trends in Welding Equipment:

Lightweight welder designs improve portability without compromising power. Smart technology integration provides real-time feedback during welding processes. Enhanced cooling systems prevent overheating during prolonged use.Conclusion

The future of metal fabrication looks brighter than ever due to continuous innovations paving the way for efficiency, sustainability, and enhanced safety measures across various sectors—be it construction, automotive manufacturing, or aerospace engineering—every industry stands to benefit from advancements such as robotic automation and additive manufacturing technologies coupled with traditional methods like Mig welding or Tig welding services available nationwide including options like mobile welding services right here in Phoenix!

FAQs About Metal Fabrication Innovations

What are some common techniques used in metal fabrication?

Some common techniques include Mig welding, Tig welding, Arc welding, plasma cutting among others which serve different purposes based on project requirements.

How does robotic automation impact productivity?

Robotic automation increases productivity by performing tasks quickly & consistently without fatigue thereby reducing operational costs over time while enhancing overall quality control processes too!

Are there sustainable practices within the industry?

Absolutely! Many companies recycle scrap metals & utilize energy-efficient equipment while adopting eco-friendly practices during production stages contributing towards greener manufacturing solutions overall!

What makes 3D printing revolutionary?

3D printing offers unparalleled design freedom allowing creators unlimited possibilities combined with reduced waste output making it an appealing alternative compared against conventional machining approaches currently dominating markets today!

Why is safety crucial during weldings?

Safety ensures protection against workplace hazards including burns & exposure risks thus implementing protocols helps safeguard workers lives ultimately leading towards better long-term outcomes both financially & ethically speaking alike too!

How do advanced materials improve fabrications?

Advanced materials offer superior properties such as lightweight yet durable alternatives enabling improved performance characteristics across various applications ranging from aerospace components through automotive assemblies etc., thus enhancing overall effectiveness significantly!

In summary—embracing these innovations will undoubtedly shape not just our present but also define tomorrow’s landscape where efficient workflows meet sustainable growth strategies aligning perfectly well within modern industrial environments worldwide today!